Intumescent paint for wood is the most effective type of fire-retardant coating for structural wood protection and critical applications. When exposed to intense heat (typically >250°C/482°F), it undergoes a dramatic physical transformation to form a thick, insulating char layer that shields the underlying wood, delaying ignition and structural failure.

Intumescent paint for wood is the most effective type of fire-retardant coating for structural wood protection and critical applications. When exposed to intense heat (typically >250°C/482°F), it undergoes a dramatic physical transformation to form a thick, insulating char layer that shields the underlying wood, delaying ignition and structural failure.

🔥 How It Works (The Science)

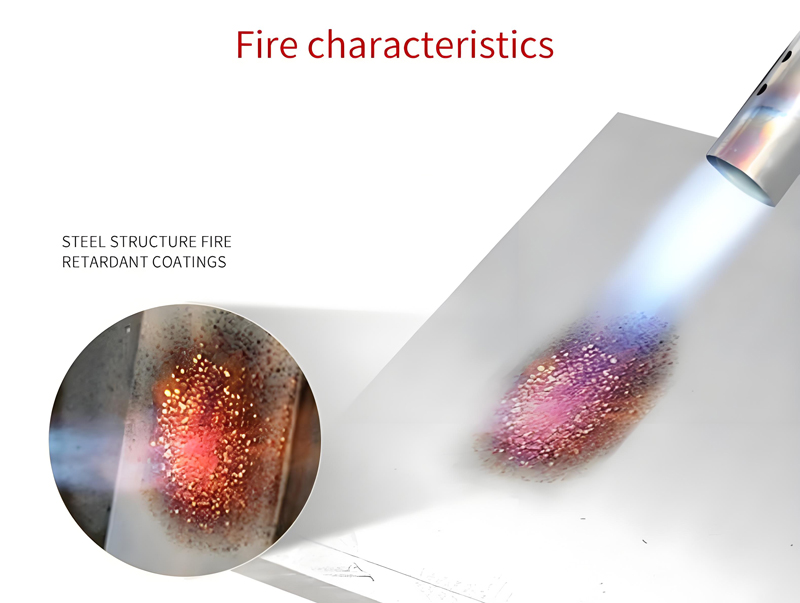

Swelling Reaction: Heat triggers chemical components (like ammonium polyphosphate, pentaerythritol, and melamine) to react.

Gas Release: Blowing agents release non-flammable gases (e.g., ammonia, water vapor, CO₂).

Char Formation: The gases cause the softened coating to expand dramatically (up to 50x its original thickness!).

Insulating Barrier: The resulting rigid, carbon-rich foam char acts as a physical and thermal barrier:

Insulates: Slows heat transfer to the wood substrate.

Protects: Shields wood from oxygen and direct flame contact.

Delays Pyrolysis: Prevents wood from breaking down into flammable gases.

✅ Key Advantages

Superior Fire Resistance: Offers the highest level of fire protection for wood among paint types (Class A ratings common).

Structural Integrity Protection: Crucial for load-bearing beams, columns, and frames - buys critical time for evacuation and firefighting.

Reduced Flame Spread: Significantly slows lateral flame propagation.

Reduced Smoke & Toxicity: Many formulations suppress smoke generation.

Code Compliance: Essential for meeting fire safety standards in commercial, public, and multi-residential buildings.

⚠️ Critical Considerations & Limitations

Appearance of Intumescent paint for wood:

Typically dries to an opaque, often slightly textured or orange-peel finish.

Thickness required for protection is usually visible.

Topcoats: Many intumescents can be overcoated with compatible decorative paints (latex, acrylic, specific fire-rated topcoats). VERIFY COMPATIBILITY WITH THE MANUFACTURER FIRST. An incompatible topcoat can ruin fire performance.

Application Precision is PARAMOUNT:

Dry Film Thickness (DFT): Achieving the exact DFT specified by the manufacturer and certification is non-negotiable. Underspray = failure. Overspray = waste/cracking. Use wet film gauges during application.

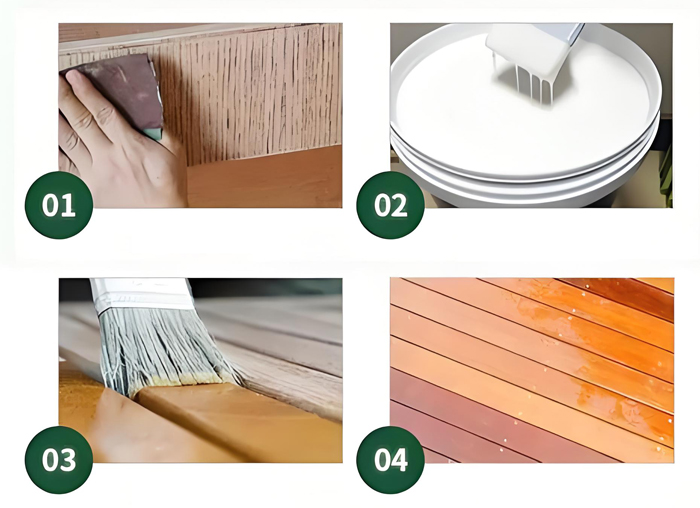

Surface Prep: Wood must be clean, dry, sound, and free of contaminants (dust, grease, old flaky paint/varnish). Sanding is usually essential for adhesion. Primers are often required (use manufacturer-specified primers).

Coats & Curing: Apply the exact number of coats needed to achieve the target DFT. Strictly adhere to recoat windows and full cure times (can be days).

Environment: Apply within specified temp/humidity ranges.

Cost: Significantly more expensive than standard paints or non-intumescent fire retardants.

Durability & Maintenance:

The intumescent layer is fragile once cured. Avoid abrasion or impact.

UV exposure degrades performance rapidly. Primarily for INTERIOR use. Exterior use requires specific UV-stable topcoats (verify certification).

Requires periodic inspection and recoating per the manufacturer's schedule (often 5-15 years depending on environment).

Certification: MUST be independently certified (UL, Intertek, FM Global, etc.) to recognized standards (e.g., ASTM E84 for surface burning, ASTM E119/UL263 for fire-resistance ratings on assemblies) specifically for wood substrates. Don't assume a paint certified for steel works on wood.